FAQ

Yes, metal twist caps are suitable for hot-fill or high-temperature applications. They can withstand the heat and sealing pressures involved in processes like hot-filling or pasteurization. However, it is important to discuss your specific requirements with our team to ensure the caps are suitable for your particular application.

Metal twist caps can be manufactured to fit various bottle or jar sizes. Depending on your specific packaging needs, we can provide options for different cap diameters and heights to ensure a proper fit for your containers.

To ensure compatibility with your existing capping equipment, it is recommended to provide us with details about your equipment specifications, such as the threading type, cap application method, and any other relevant information. This will help our team to guide you in selecting the appropriate metal twist caps that work seamlessly with your machinery.

Choosing the right automatic capping machine involves considering factors like your production volume, container and cap specifications, budget, and any specific requirements you may have. It is advisable to consult with a capping machine supplier or manufacturer who can guide you in selecting the most suitable machine for your application.

Yes, automatic capping machines can be customized to accommodate specific packaging requirements. This includes features such as adjustable torque settings, cap tightness control, and specialized handling mechanisms to suit unique container and cap designs.

Yes, automatic capping machines are available in different models and configurations to cater to various production volumes. Whether you have a small-scale operation or a high-speed production line, there are machines available to meet your specific volume requirements.

Regular maintenance is important to keep your automatic capping machine running smoothly. This typically involves routine cleaning, lubrication, and inspection of components. Some machines may require specific maintenance tasks like changing belts or replacing worn parts. It is recommended to follow the manufacturer's maintenance guidelines for optimal performance.

Yes, non-stocked closures require a minimum order quantity. Quantity will vary by size

Minimum run quantities vary per cap diameter from 60,000 to 200,000

Please visit https://oehha.ca.gov/proposition-65/about-proposition-65 for information regarding Proposition 65

Yes, we offer BPA Non-intent closures

We stock most diameters in black, gold and white

Send an email to sfair@massilly.com and we will have an account manager reach out to you

You should answer these questions:

- What is the GPI finish number of your glass?

- What type of product will I be capping? Do I want a shallow skirt or a deep skirt

- Do you require a cap for pasteurization or sterilization?

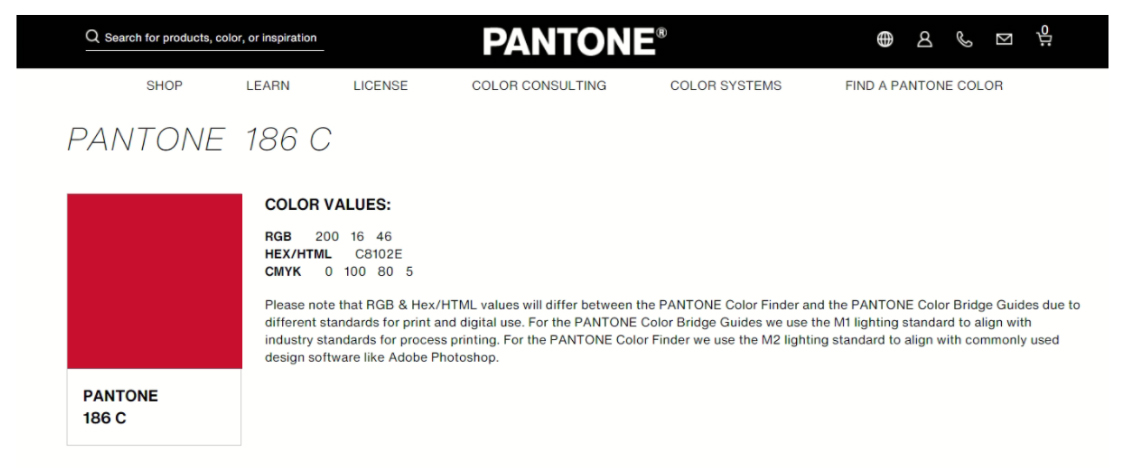

- What colour do I want my caps to be?

- Do you require a safety button?

- How many caps do I need?

- By when do I need them?

Our office and warehouse are located at 406 Elgin Street, Brantford, ON, Canada, N3S 7P6

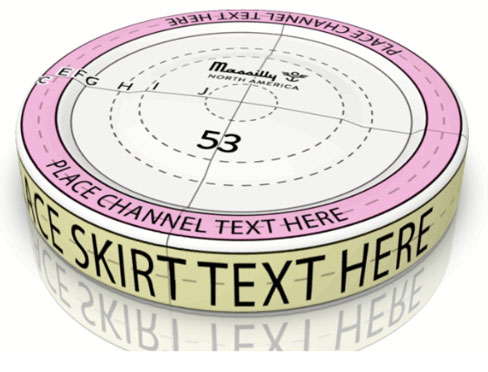

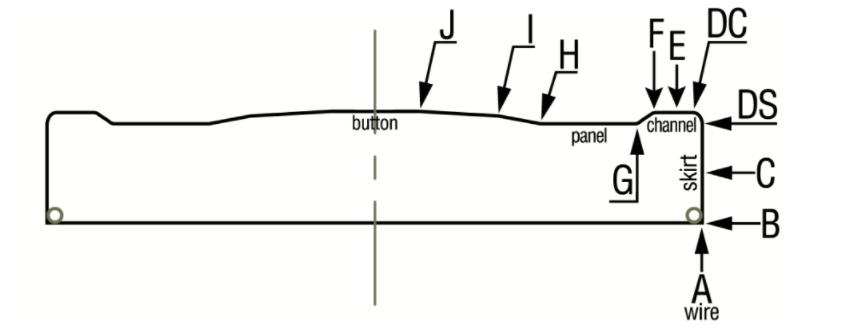

Panel, Channel and Skirt

The panel is the top of the cap available with or without a button. Most of our caps have a wide channel, where you can place text. Text is not recommended on a Narrow Channel. Narrow Channel caps allow for jars to be stacked on top of each other.

Example of a Narrow Channel

Yes, side profiles are available on the dieline that can be requested from your Account Coordinator.

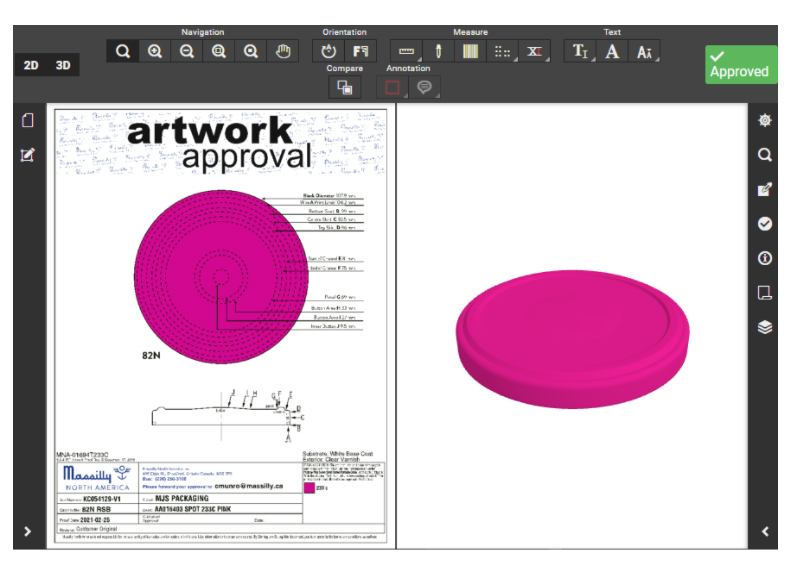

Please contact your Account Coordinator to get a New Item Request filled out. Artwork may be submitted via email.

After submitting your artwork, your artwork will be reviewed and a proof and 3D rendering will be created for you to approve on our “Share and Approve’ website.

4-6 colours is usually the max

We use the latest Adobe Cloud version of Illustrator, Indesign, Photoshop and Acrobat and recommend vector graphics for reproduction.

We prefer outlined vector files with embedded images in an ai, eps or pdf format

Thank you for your interest in Massilly North America. No, you do not need to follow up, your resume will go to our HR department. Please note that if you are selected for an interview, you will be contacted by phone or email.

Yes, your resume will be kept on file for 3 months. If a position becomes available that aligns with your background and specific skill set, we will reach out to you.

Only those who are selected for an interview will be contacted.

Yes, all permanent, full time employees are eligible for Health Benefits after 3 months of employment.

Yes, we are located on the bus route on Elgin Street.

That’s not necessary, either way of submitting an application works.

Just your positive attitude!

No, we have a wide range of machines that suit every customer's needs. Many are custom-built to your specifications.

No, the Capping Machine needs to be fed with steam. It is designed to distribute the steam to all the necessary locations to make a perfect seal. That includes steam to warm the caps and to flush the headspace.

That depends on your product. A hot-filled product will pull a vacuum once cooled. A steam fed machine will pull a vacuum when the product is still hot. This will ensure that you have a well-sealed product prior to cooling.

The standard lead time is 16 - 20 weeks. However, we do have some machines in stock, to a generic design which is suitable for most customers' needs.

The Capping Machines are sized based on maximum speed and automation. We have speeds from 10 Jars per minute in a manual operation to 500 Jars per minute with a fully automated setup.

Each Capper needs electrical, steam, water, and compressed air connections. The electrical voltage can be customized to your requirements.